New Technology – Thermo-Electric Separation Copper Substrate

- Iva Leung

- Jan 13, 2024

- 1 min read

Updated: Jan 14, 2024

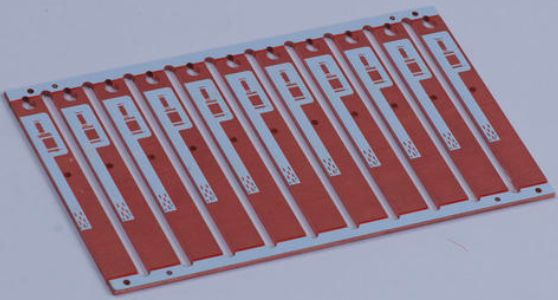

Thermo-electric separation copper substrate, as a novel technology representing the next generation of solid-state devices, boasts key advantages such as meeting high-power heat dissipation requirements, extending lifespan, and being environmentally friendly. The technology behind thermo-electric separation is relatively intricate, with high production difficulty. The substrate itself comprises layers including the circuit layer, solder resist layer, silk screen character layer, with LED chips soldered on the top side and a pure copper surface on the reverse side.

In some cases, manufacturers may utilize solar white oil with a high reflectance, earning it the moniker "solar white oil copper substrate." Our ceramic substrate expert notes that high thermal conductivity substrates disperse heat rapidly at the solder points, requiring a higher wattage soldering iron for flawless welding. On the other hand, low thermal conductivity substrates have solder points relatively insulated from the substrate. In the position under the copper substrate, insulation layers are drilled through, copper layers are applied to expose the aluminum board, and a metal layer suitable for soldering is plated onto the exposed aluminum after repeated research, discussion, and processing.

The processing sequence involves zinc immersion, followed by nickel plating on the zinc surface, copper plating on the nickel surface, and finally, tin spraying or gold plating on the copper surface. This sequence ensures strong adhesion and excellent thermal conductivity.

Comentarios